Hi! It's me, Alfaz Khan.

I am currently a Product Manager at Keelworks Foundation.

— Fueled by ADHD, powered by resilience

Fueled by coffee, driven by cars, and always ready for the next adventure. ADHD isn't a limitation—it's my secret weapon for thinking differently, staying relentless, and turning every obstacle into a new route. If I've done it once, I can shift gears and do it again.

— Skills

Supply Chain Analysis

Lean Six Sigma

ERP SAP System

Demand Forecasting

Inventory Management

Project management

Product management

— Work experience

Lead Product Manager

KeelWorks Foundation / December 2024 - Present

• Led the development of an internal volunteer management portal by leading product roadmap creation, feature prioritization, and cross-functional alignment.

• Managed collaboration across backend/frontend developers, designers, and project managers to bring delayed projects back on track using phased rollouts and weekly Scrum meetings.

• Created MVP documentation, SOPs, and onboarding manuals tailored to different user groups, improving team onboarding and role clarity.

• Utilized Figma for design handoff and maintained a live changelog for developers to streamline feedback and implementation cycles.

• Drove platform scalability planning, including architecture for future feature integration, onboarding capacity for new users, and peak usage optimization.

Project Implementation Consultant

MINEMAN Systems / July 2021 - July 2023

• Standardized 220+ SOPs for production and warehouse processes across multi-site operations.

• Used Lean Six Sigma tools to identify workflow bottlenecks, reducing operational delays by 20%.

• Built vendor evaluation dashboards, leading to improved OTIF rates and better contract terms.

• Managed cross-functional teams for process audits, UAT trials, and KPI monitoring.

Summer Intern

Larsen & Toubro / May 2019 - July 2019

• Gained in-depth insights into project management within the Upstream Oil & Gas sector, deploying lean methodologies to optimize project workflows.

Supply Chain Manager

Cloth Wagen / April 2014 - December 2016

• Led end-to-end supply chain operations for event merchandise production, covering procurement, inventory, and vendor relations.

• Implemented Kanban-based inventory planning and SAP MRP, reducing excess stock by 22% and improving turnover.

• Negotiated with suppliers to resolve quality issues, avoiding $12K in potential scrap costs and improving vendor scorecards.

• Redesigned warehouse layout and bin allocation, cutting retrieval times by 33% and boosting picking efficiency.

— Education

Rutgers Business School, New Brunswick

Master's degree, Supply Chain Analytics / 2023 - 2024

NMIMS University, Mumbai

Bachelor's degree, Mechanical Engineering / 20`16 - 2020

NMIMS University, Mumbai

Associate's degree, Robotics and IoT / 20`19 - 2021

— Projects

Volunteer Performance Tracking System (Inspired by KPIs)

KeelWorks Foundation / December 2024 - July 2025

• Developed a performance tracking system modeled on SAP KPI frameworks to monitor volunteer engagement, task completion, and feedback scores.

• Enabled data-driven allocation of volunteers to roles that matched their strengths, reducing talent misalignment.

• Improved project fit and volunteer retention by 22% over 3 months.

Capstone Project – Standardizing End-of-Life & Last Time Buy Process

Becton, Dickinson and Company / January 2024 - May 2024

• Audited existing SOPs for the SCR portal via workshops with procurement and engineering teams.

• Designed a preventive strategy for critical components by developing risk weighted alternate sourcing matrix.

• Actionable recommendations improved procedural adherence by 25% within two months.

Automated Test Script Generator for SAP UAT (GPT-Integrated)

MINEMAN Systems Pvt. Ltd. / January 2024 - May 2024

• Developed an AI-powered internal tool using GPT to automate creation of UAT test scripts from SOPs and functional flows.

• Reduced manual effort by 40% and standardized test documentation across SAP PP, QM, and WMS modules.

• Saved 45 hours annually per employee in QA and testing cycles; improved test coverage consistency by 60%.

AI-Driven Automation for Test Documentation

MINEMAN Systems Pvt. Ltd. / January 2024 - May 2024

• Designed and deployed a ChatGPT-based system to automate the creation of functional test cases and documentation across SAP modules using a fixed template for standardized format.

• Reduced manual documentation effort by 35%, saving approximately 45 hours annually per employee across QA and implementation teams.

• Trained internal teams to integrate AI tools into UAT workflows, enhancing process consistency.

Autonomous Ground Vehicle - Mechanical Designer

Team D.A.R.V.I.N / September 2019 - May 2021

• Led the development of a robust and efficient chassis for Team D.A.R.V.I.N's entry into the Intelligent Ground Vehicle Competition (IGVC), Michigan 2020, optimizing for performance and durability.

• Innovated in design and oversaw the procurement of high-quality materials, contributing significantly to the team's ability to create an advanced autonomous ground vehicle.

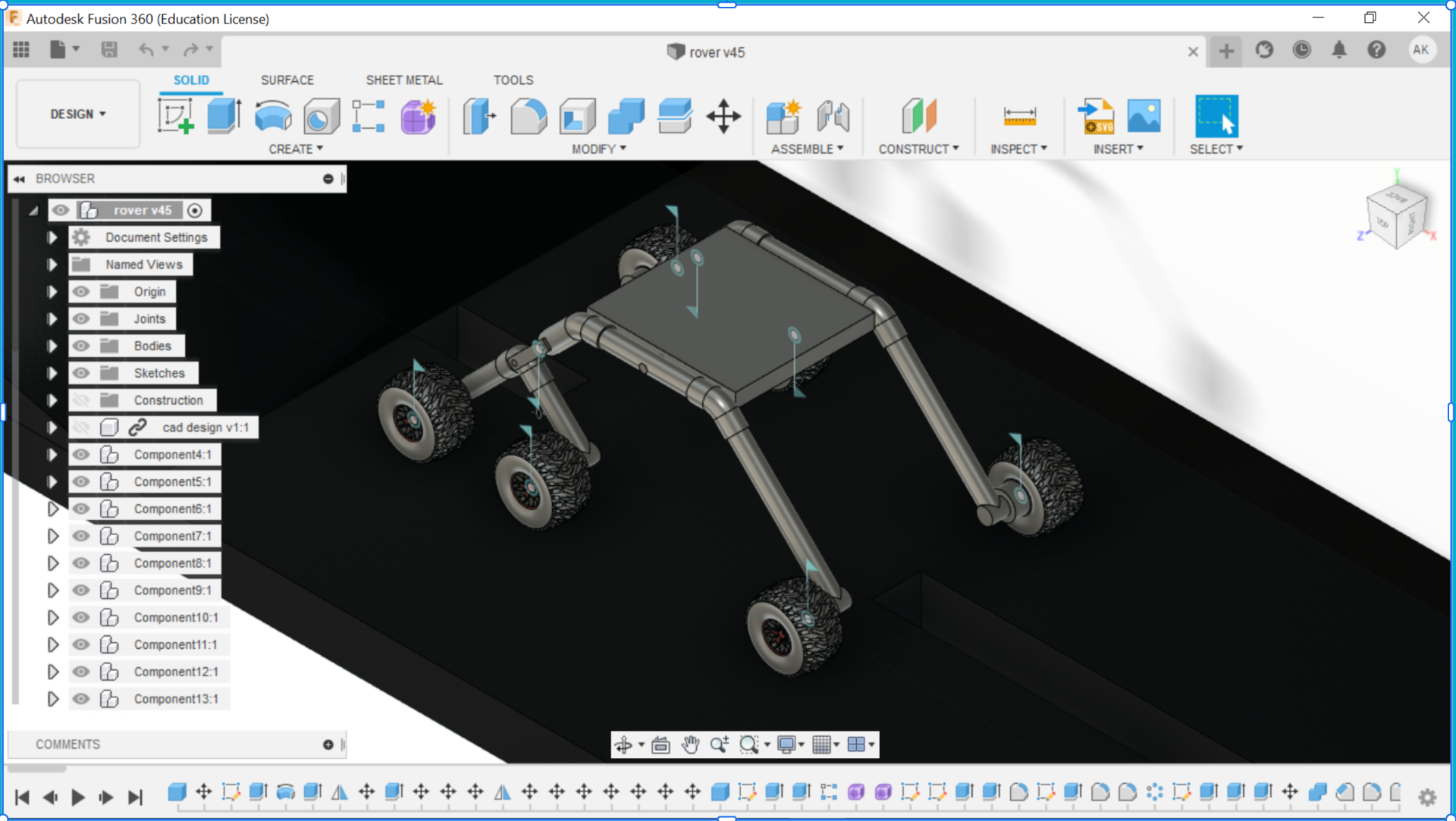

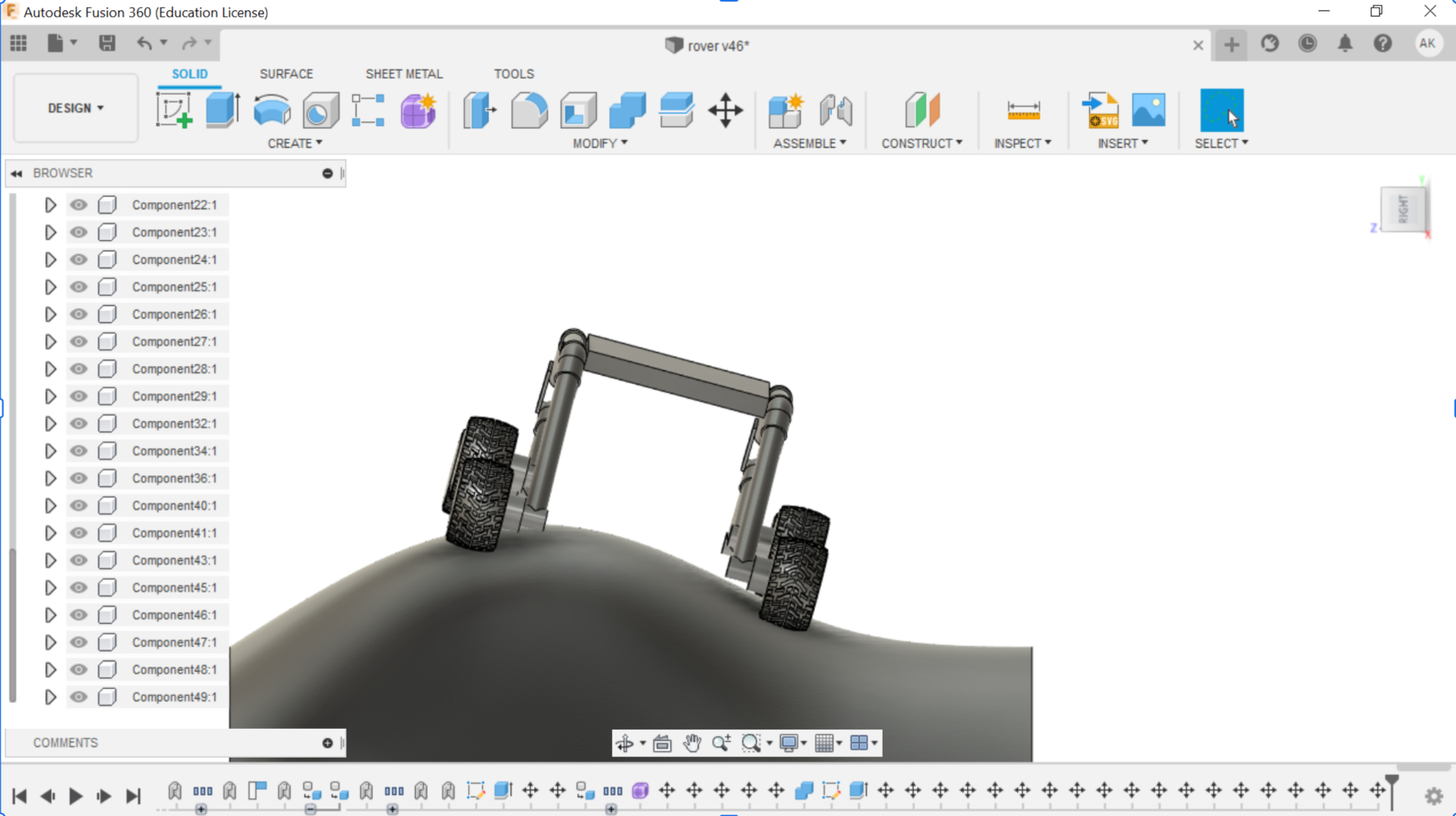

Design and Control of Multi-Terrain Rover

Mechanical Engineering Final Year Project/ September 2019 - May 2021

Tools: Fusion 360, Arduino UNO, Unity 3D, PVC prototyping

• Designed and developed a rugged rover prototype using a rocker-bogie suspension system to traverse uneven, obstacle-rich terrain with up to 45° incline support.

• Engineered 6-wheel independent motor control and implemented skid steering to enable non-slip, high-traction movement across soft and rough surfaces.

• Created a complete 3D model and terrain animation in Fusion 360; validated performance on virtual terrain scenarios.

• Programmed remote control functionality via Arduino UNO with web-based communication enabling internet-based real-time control.

• Integrated sonar sensors for real-time terrain mapping and visualized the rover's path in Unity 3D, demonstrating a modular, scalable rover platform.

• Explored future use cases including bomb disposal, disaster relief mobility, transport in inaccessible terrains, and mobility assistance solutions.

Lean Production Uplift: Reduced Cycle Time via Line Balancing and PFMEA

Cloth Wagen / September 2019 - May 2021

• Led a cross-functional Lean Six Sigma initiative to rebalance production lines using PFMEA, time analysis, and bottleneck simulations.

• Eliminated redundant workstations and introduced one-piece flow cells, aligned with SAP PP schedules.

• Reduced production cycle time by 28%, cut WIP inventory by 35%, and increased throughput by 22% without adding headcount.

"Every time I face a seemingly insurmountable challenge, I remind myself of past obstacles I've overcome and think - If I've done it once, I can do it again."

— Certifications

Learning Minitab

National Association of State Boards of Accountancy (NASBA) / 2024

CSCMP Supply Chain Foundations: Demand Planning Professional Certificate

CSCMP - Council of Supply Chain Management Professionals / 2024

PMI Operational Excellence Foundations

Project Management Institute / 2024

Six Sigma: Green Belt

LinkedIn / 2024

Six Sigma Foundations

LinkedIn / 2024

Excel Supply Chain Analysis: Solving Inventory Problems

LinkedIn / 2024

PMI Root Cause Analysis: Getting to the Root of Business Problems

Project Management Institute / 2024

Inferential Statistical Analysis with Python

Coursera / 2023

Entrepreneurship Capstone

Coursera / 2021

Initiating and Planning Projects

Coursera / 2023

Understanding and Visualizing Data with Python

Data Science Math Skills

Coursera / 2023

Coursera / 2021

Basic Data Descriptors, Statistical Distributions, and Application to Business Decisions

Coursera / 2023

Statistics Foundations 3: Using Data Sets

LinkedIn / 2023

Statistics Foundations 4: Advanced Topics

LinkedIn / 2023

Computational Vision

Coursera / 2021